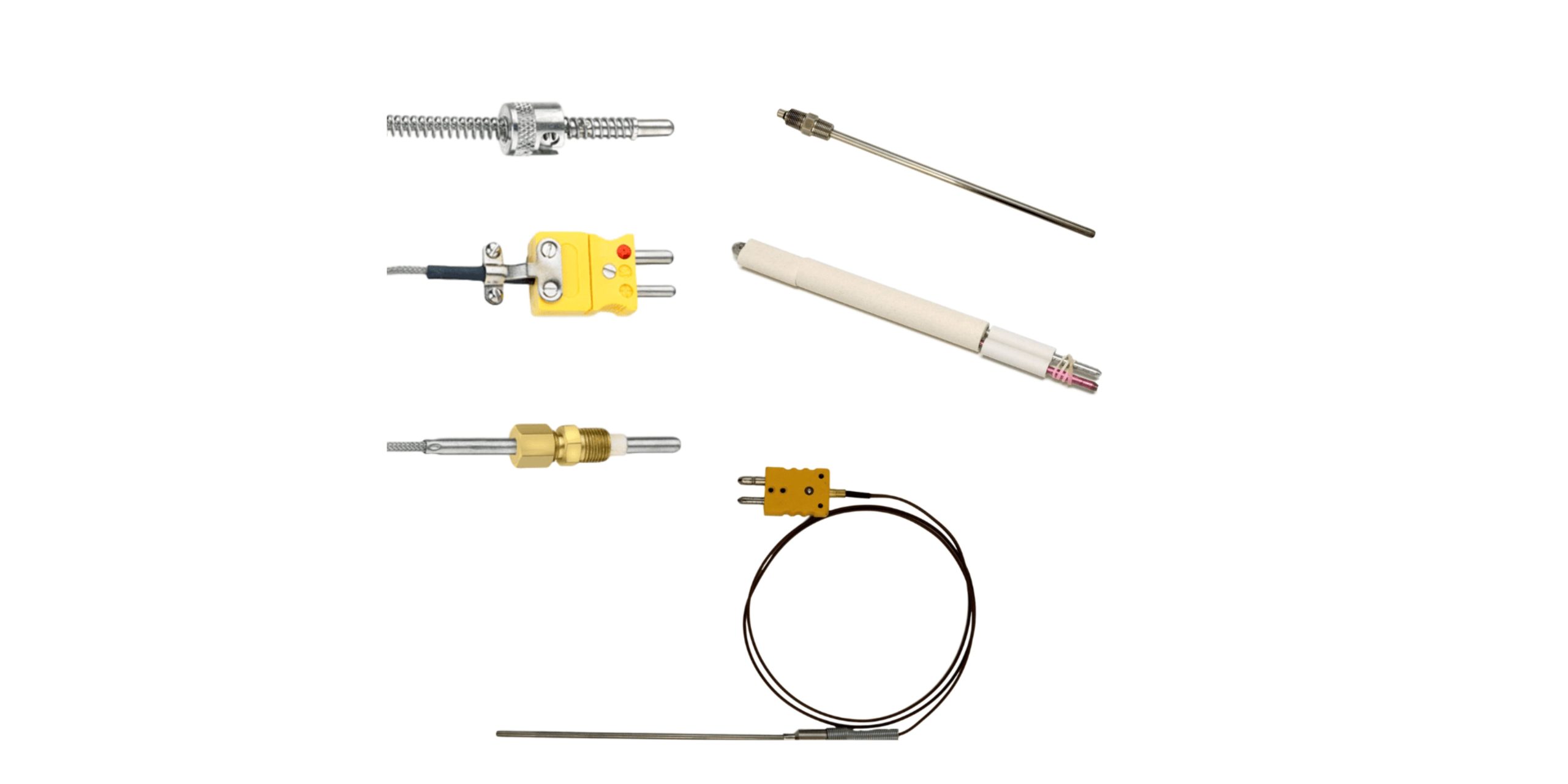

Custom Thermocouple Types adapted to your Testing Process

Choosing the right thermocouple for your testing or manufacturing process is essential to collecting accurate data and ensuring product quality and consistency. In another article, we discussed some considerations that should be made when selecting your thermocouples, such as the process temperature range and chemical environment, the thermocouple response time, and the physical location where measurements will occur. Once you’ve defined the operating parameters and determined your thermocouple requirements, it’s time to navigate an alphabet soup of thermocouple types to make your selection.

Thermocouples come in various types, each with unique alloyed wire compositions. The wires’ properties determine the thermocouple’s operating temperature range, accuracy level, and process environment specifications. When choosing a thermocouple, you must compare these characteristics with your testing requirements. With that in mind, let’s discuss a few common thermocouple types and when the most common thermocouple type might not be the best choice.

Popular thermocouples: Type K, Type J, and Type T

Type K thermocouples are often selected because they are a durable and low-cost option suitable for a variety of industrial processes and testing. These thermocouples are prevalent because they operate over a wide temperature range: a few hundred degrees below zero to above 2000°F. Type K thermocouples are commonly used to measure the high temperatures of chemical production, automotive engines, and some power generation processes.

Even though they might seem like an all-purpose thermocouple, Type K thermocouples are not always appropriate for certain testing and manufacturing processes. For example, Type K thermocouples excel in most chemical environments, but may not perform well in processes that include reducing atmospheres. If this scenario applies to you, then consider a Type J thermocouple. These thermocouples also work well at vacuum-level pressures. Type J does not have as wide of an operating temperature range as Type K, but they are similar in accuracy and cost.

What about precisely measuring cold temperatures? Type T thermocouples may be preferable to Type K despite Type K’s wide temperature measurement range. Type T can withstand most chemical atmospheres, but can also measure extremely low temperatures with greater accuracy. These thermocouples are often suitable for the food industry where the process temperatures are well below zero and accurate measurements are crucial to product safety.

A new frontrunner in temperature measurement: Type N Thermocouples

At K-Tec Systems, we are working with many industries to upgrade Type K thermocouples to Type N thermocouples for many manufacturing and testing processes. These two thermocouple types operate over the same temperature range and in similar operating conditions, but tweaks in the wire composition give Type N longer lifespan and greater stability at very high operating temperatures. As a result, Type N thermocouples are gaining traction especially in the automotive industry and in heat treating processes. While Type N thermocouples have a slightly higher base price, their longer lifespan may make them an economical choice for harsh operating environments – and with the added benefit of more reliable measurement at very high temperatures.

The next steps in choosing the right thermocouple

Choosing the right thermocouple type for your process is a great first step in planning your temperature measurement strategy. Keep in mind that other factors, such as wire diameter, wire insulation, and thermocouple sheaths must also be carefully chosen for your application. That’s why we recommend consulting an expert at K-Tec Systems.

K-Tec Systems can help you choose the best accurate thermocouple to meet your testing needs. Contact us today.