Airflow Measurement, Flow Probes, Aerodynamics in Wind Tunnel

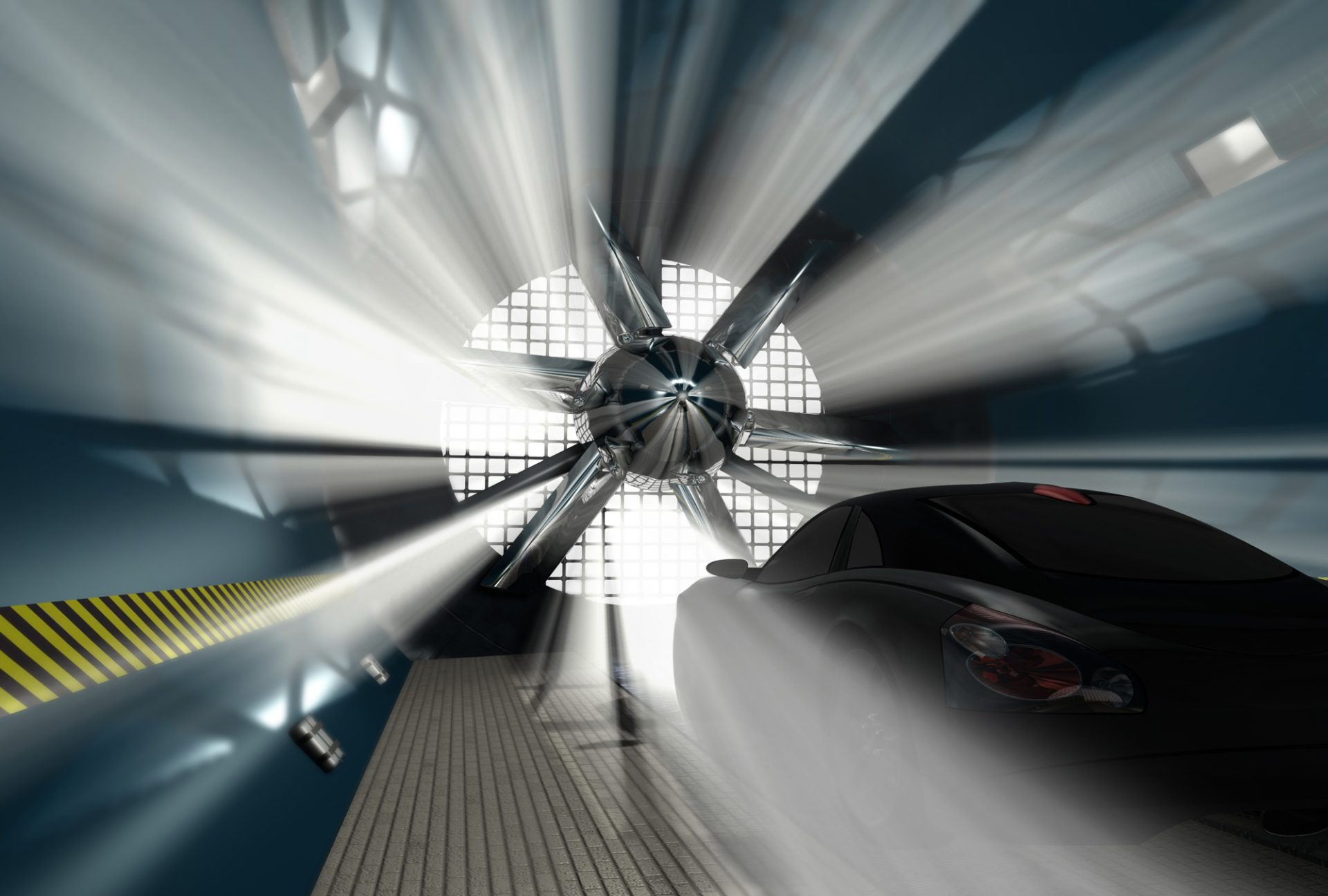

When we think of wind tunnels, we typically imagine a car inside a room with a large, spinning fan.

At K-Tec Systems, we think about automobiles in wind tunnels, too. Climatic wind tunnels are also used to understand the aerodynamics of airplanes, trucks, drones, rockets, racing cars, and anything else that might encounter air resistance. They may be large enough to study the airflow around an entire vehicle, or they may be smaller for measuring airflow around a scale model or around a single component of a vehicle.

The airflow around these objects must be well understood so designs can improve: perhaps to increase a car’s fuel economy or enhance an airplane’s safety in turbulent weather. To understand the aerodynamics of vehicles and aircraft, the pressures, flow velocities, and flow angles of the air around them must be measured accurately.

Measuring Aerodynamics in a Wind Tunnel

Flow probes for wind tunnels

Multi-hole probes and Kiel probes are two examples of flow measurement devices that can be strategically placed inside a wind tunnel for measuring pressure, velocity, and flow angle. The ideal probe can take fast, accurate measurements and withstand the wind tunnel environment, yet it must be small enough that it does not interfere with the flow profile in the wind tunnel. Our partner, Vectoflow, designs and manufactures these types of high-performance devices, so we’ll talk about their custom, state-of-the-art probes.

Multi-hole probes

Vectoflow utilizes additive manufacturing to create durable custom probes that can meet the requirements of your testing application. Based on Bernoulli’s principle, 3-, 5-, 7-, or 14-hole probes measure static and dynamic pressures at the probe tip. They come in four geometries: straight, L-shaped, cobra, and drilled elbow. Because they can be made of stainless steel, titanium, Inconel, or ceramics, these probes can withstand high temperatures, up to around 1800°C (3200°F).

Vectoflow also offers fully customized multi-hole probes that can be almost any geometry. Since you can specify additional pressure holes, fully customized probes can measure airflow angles of up to ±160° and velocities of 3 m/s (10 ft/s) up to Mach 2.

Thermocouples can also integrate into multi-hole probes for measuring air temperature inside a wind tunnel.

Kiel probes

Vectoflow custom designs Kiel probes that measure total airflow pressure within flow angles of ±60°. Because Vectoflow uses additive manufacturing to produce Kiel probes, the measurement tips can be as small as 1.6 mm, and the probe material can withstand temperatures up to around 1800°C (3200°F).

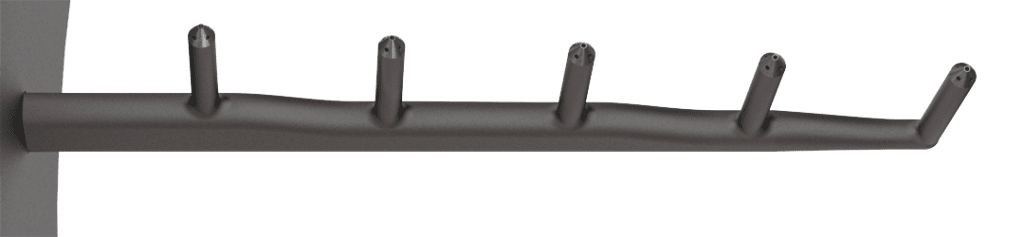

Rakes in a wind tunnel

For increased spatial resolution, rakes are commonly used in wind tunnel testing applications. When probes are configured as a rake, each “tine” contains a multi-hole or Kiel probe that is strategically placed inside the wind tunnel around the object being tested. The use of rakes allows for a fuller understanding of the object’s aerodynamics.

Contact K-Tec Systems

Vectoflow’s flexible additive manufacturing approach creates flow measurement devices that can be highly customized for wind tunnel testing applications. Probe geometries and materials are selected to withstand high flow velocities, variable flow angles, and high temperatures while providing complete, accurate flow data. Contact K-Tec Systems to learn how Vectoflow probes can help you understand the aerodynamics of your vehicle or aircraft.

K-Tec systems is the U.S. distributor for Vectoflow.

Please contact us at 248-414-4100 if you have any questions.